Rexroth Original M-3SED Directional Seat Valve With Solenoid Actuation

Size 6

Component series 1X

Maximum operating pressure 350 bar [5100 psi]

Maximum flow 25 l/min [6.6 gpm]

General

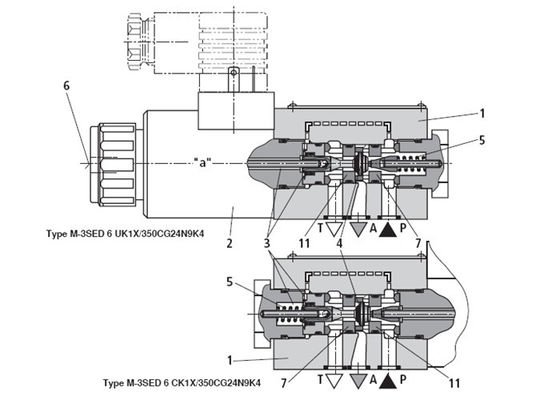

The directional valve type M-.SED is a direct operated directional seat valve with solenoid actuation. It controls start, stop and direction of the flow and basically comprises a housing (1),solenoid (2), valve seats (7) and (11) and closing element (4).

The manual override (6) allows for the operation of the valve without solenoid energization.

Basic principle (3/2 directional seat valve) The initial position of the valve (normally open “UK” or normally closed “CK”) is determined by the arrangement of the

spring (5). The chamber (3) behind the closing element (4) is connected to port P and sealed against port T. Thus, the valve is pressure-compensated in relation to the actuating forces (solenoid and spring).

Due to the special closing element (4), ports P, A, and T can be loaded with the maximum operating pressure (350 bar) and the flow can be directed into both directions (see symbols). In the initial position, the closing element (4) is pressed onto the seat (11) by the spring (5), in operated position onto the

seat (7) by the solenoid (2). The flow is blocked.With the 2/2 directional seat valve, the tank port is blocked internally.

Features

– Direct operated directional seat valve with solenoid actuation

– Porting pattern according to DIN 24340 form A (without locating hole)

– Porting pattern according to ISO 4401-03-02-0-05 and NFPA T3.5.1 R2-2002 D03 (with locating hole)

– Safe switching also with longer standstill periods under pressure

– Wet-pin DC voltage solenoids with detachable coil (AC voltage possible by means of a rectifier)

– Solenoid coil can be rotated by 90° – The coil can be changed without having to open the pressure-

tight chamber.

– Electrical connection as individual connection (for more electrical connections, see RE 08010)

– With concealed manual override, optional

– Inductive position switch (contactless), see RE 24830

Ordering Details for Choosing model Number

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!